This is how I easily removed and installed the PCV valve:

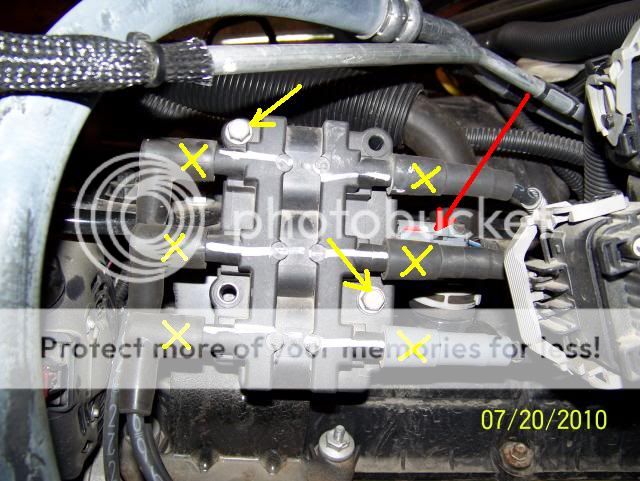

Removing the coil pack is easy to do, and greatly improves access to the PCV valve.

Disconnect all six plug wires at the coil pack. The stock wires and the coil pack terminals are numbered, so no need to worry about marking them.

Remove the two bolts marked with yellow arrows.

Leave the main electrical plug, marked with red arrow, connected.

Rotate the coil pack up and out of the way. It will tuck in behind some of the wires, and stay there.

![Image]()

Now that you have plenty of room to work, remove the clamp from the PCV hose. Pliers will do it, but a hose clamp tool designed for this type of clamp will make it easier.

![Image]()

You now can see the PCV valve recessed into the adapter.

![Image]()

Put a zip tie on the neck, as pictured. Grab the zip tie with some pliers. Rest the nose of the pliers on the intake manifold, as in the picture.

![Image]()

Pry up with the pliers. The Valve comes out so fast and easy, it actually may make a "pop".

![Image]()

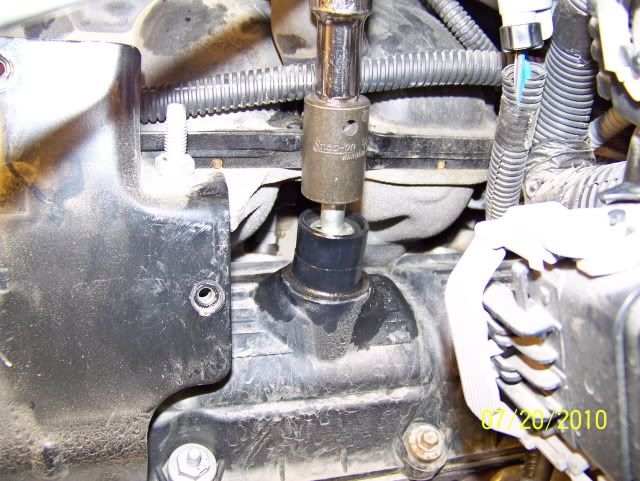

Place the new valve in the adapter. It will be hard to push home, so get a socket just big enough to fit in the adapter. The socket wall should be thick enough so it will push the valve, and the rubber seal.

An extension on top, long enough to stick above neighboring lines, will allow you to push or tap the valve home.

![Image]()

Here is a pic of the valve after seating it with the socket.

Reconnect the hose with the clamp, to the PCV adapter.

Reinstall the coil pack, connect the wires to the appropriate terminals.

When you push the plug wires onto the terminals, make sure you hear them snap into place.

Remove all tools from the engine bay.

![Image]()

Here is a link to how the valve works:

http://www.jkowners.com/forum/showthread.php?t=35277

Removing the coil pack is easy to do, and greatly improves access to the PCV valve.

Disconnect all six plug wires at the coil pack. The stock wires and the coil pack terminals are numbered, so no need to worry about marking them.

Remove the two bolts marked with yellow arrows.

Leave the main electrical plug, marked with red arrow, connected.

Rotate the coil pack up and out of the way. It will tuck in behind some of the wires, and stay there.

Now that you have plenty of room to work, remove the clamp from the PCV hose. Pliers will do it, but a hose clamp tool designed for this type of clamp will make it easier.

You now can see the PCV valve recessed into the adapter.

Put a zip tie on the neck, as pictured. Grab the zip tie with some pliers. Rest the nose of the pliers on the intake manifold, as in the picture.

Pry up with the pliers. The Valve comes out so fast and easy, it actually may make a "pop".

Place the new valve in the adapter. It will be hard to push home, so get a socket just big enough to fit in the adapter. The socket wall should be thick enough so it will push the valve, and the rubber seal.

An extension on top, long enough to stick above neighboring lines, will allow you to push or tap the valve home.

Here is a pic of the valve after seating it with the socket.

Reconnect the hose with the clamp, to the PCV adapter.

Reinstall the coil pack, connect the wires to the appropriate terminals.

When you push the plug wires onto the terminals, make sure you hear them snap into place.

Remove all tools from the engine bay.

Here is a link to how the valve works:

http://www.jkowners.com/forum/showthread.php?t=35277